PolyOne Launches New Technologies, Highlights Design Services and 3D Printing at NPE 2015

March 17, 2015

CLEVELAND – PolyOne is gearing up with a multi-faceted presence at NPE 2015 next week, including a customer innovation center and NPE3D Printing sponsorship and exhibit. In addition, five exceptional new technologies will be unveiled at NPE, widely recognized as the premier global showcase for the plastics industry.

“We’re excited to talk with customers at NPE about the ways in which our specialty formulations, technical and design services, and innovative polymer science can be used to energize their product development process and business objectives,” said Cathy Dodd, vice president, Marketing, at PolyOne.

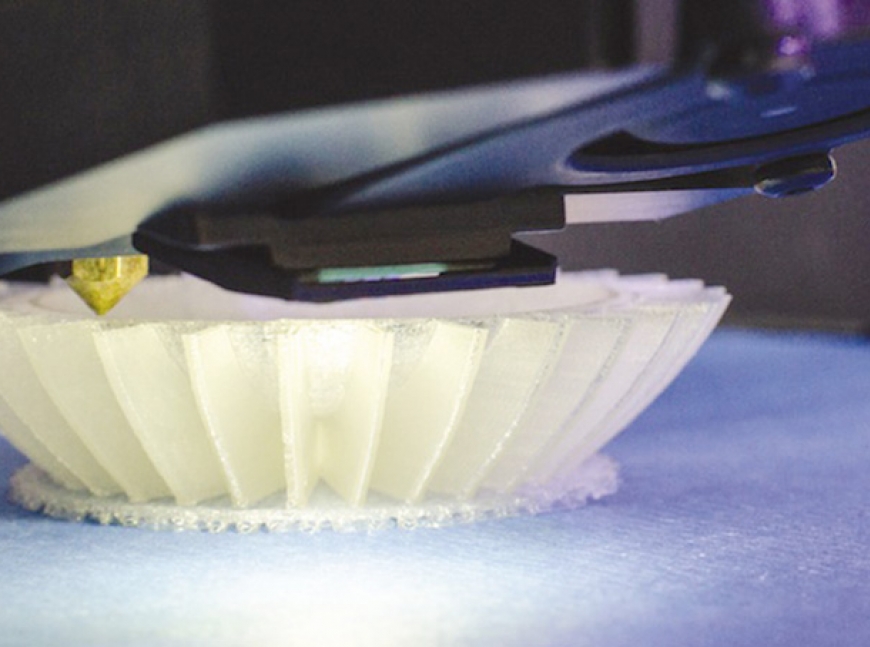

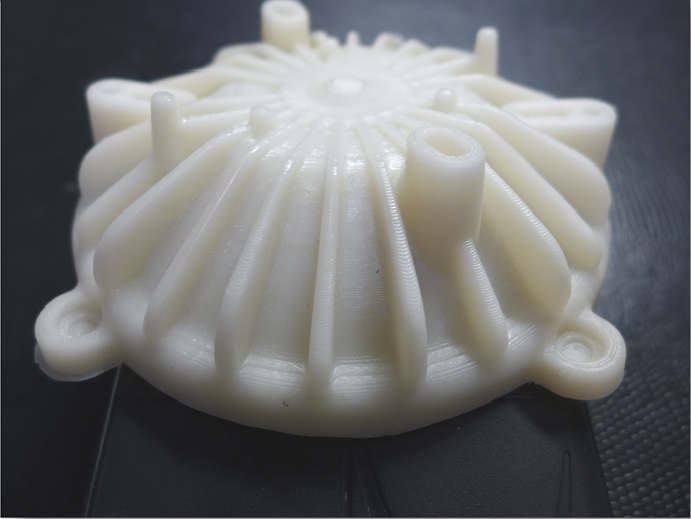

PolyOne’s customer innovation center (Room S230 BC) will highlight advanced polymer formulations that help brand owners and manufacturers grow and evolve while also enabling their customers to get more done and enjoy life more. As a co-sponsor and exhibitor at NPE3D Printing Premier (Booth S35014), PolyOne will display its progress in developing materials for 3D printing under the Ohio Third Frontier initiative, as well as examples of 3D printed prototypes and tooling.

“We are working to find ways in which 3D printing can take our customers to a new level of innovation. Together with our design resources, we are exploring this technology to help customers evaluate multiple iterations faster and optimize their manufacturing process as well as their product’s performance and aesthetics,” Dodd explained.

New technologies that will launch at NPE 2015 include:

- Geon™ BIO flexible vinyl is a non-phthalate material that offers 30% biobased content with no performance tradeoffs and excellent processability for healthcare, footwear and furniture applications.

- reSound™ NF reinforced materials are based on an eco-conscious, natural fiber-filled technology and are in current evaluations at several key automotive OEMs for use in under-the-hood, lighting, and semi-structural components.

- Geon™ Bold vinyl solutions are dark, richly colored materials that stand up to the elements, especially heat build up, without losing their intensity or performance for windows, fencing, decking, and siding.

- Versaflex™ VDT Vibration Damping TPE for Overmolding enables manufacturers of consumer electronics, power tools, sporting goods and appliances to add comfort and resilience to their products, providing a better end-user experience.

- ColorMatrix™ Select is a cloud-based liquid color creation and supply service that combines advanced liquid colorants, Web-accessed software, and automated dispensing technology to enable brand managers, converters and designers to take greater control of their color development and supply chain.

IQ Design Labs and InVisiOSM Color and Design Services will be featured at NPE as well. Combining design and market insights with specialty colorants and polymers, these services inspire creativity and leverage design, materials and color development expertise at the beginning of product development projects to reduce risk, strengthen brand equity and increase speed to market.

Additionally, a number of PolyOne experts will be speaking at the following conference events during NPE:

SPI Business of Plastics Conference

- Giles Branthwaite, Strategic Project Manager, PolyOne ColorMatrix: “Accelerating Color Development and Supply With an Innovative Liquid Color System”

- Victoria Sayer, Global Regulatory Manager, PolyOne ColorMatrix: “Achieving Global Clearance for New Food Contact Plastic Additives” and “Addressing Exposure and Toxicity in Meeting EU Regulation 10/2011 Requirements”

IDSA South Pre-Conference Design Sessions

- Chris Bray, PolyOne IQ Design: Panelist for “Bridging the Communication Gap: How to ‘Talk Designer’”

ANTEC 2015

- Jane Spikowski, PolyOne: “Fatigue Performance of Fused Deposition Modeling Style: 3D Printed vs. Injection Molded”

- Roger Avakian, PolyOne: “A Formulator’s Perspective on Meeting Needs in the Plastics Marketplace”

- Jason Zhu, PolyOne: “Comparison of Flame Retardancy Performance: Injection Molding vs. 3D Printing”

For more information on what to expect from PolyOne at NPE2015, please visit npe.polyone.com

# # #

Caption: This prototype heat sink for an LED ceiling light was molded in PVC from 3D printed inserts produced at the PolyOne Innovation Center in Avon Lake, Ohio.

To access PolyOne’s news library online, please go to www.polyone.com/news

About PolyOne

PolyOne Corporation, with 2014 revenues of $3.8 billion, is a premier provider of specialized polymer materials, services and solutions. The company is dedicated to serving customers in diverse industries around the globe, by creating value through collaboration, innovation and an unwavering commitment to excellence. Guided by its Core Values, Sustainability Promise and No Surprises PledgeSM, PolyOne is committed to its customers, employees, communities and shareholders through ethical, sustainable and fiscally responsible principles. For more information, visit www.polyone.com.

Media contact

Michelle Maniscalco

Marketing Communications Manager, North America

PolyOne Corporation

+1 440-930-1988

michelle.maniscalco@avient.com

Press Resources

Investor News

Avient Announces Third Quarter 2025 Results... More

Avient Announces Fifteenth Consecutive Annual Dividend Increase... More

Avient To Hold Third Quarter 2025 Conference Call... More