Benefits of Long Fiber Reinforced Thermoplastic Composites

Long fiber reinforced thermoplastic composites offer many unique capabilities that translate into desirable product benefits. Alone or in combination, these benefits provide meaningful motivation to utilize long fiber composites in a broad spectrum of applications.

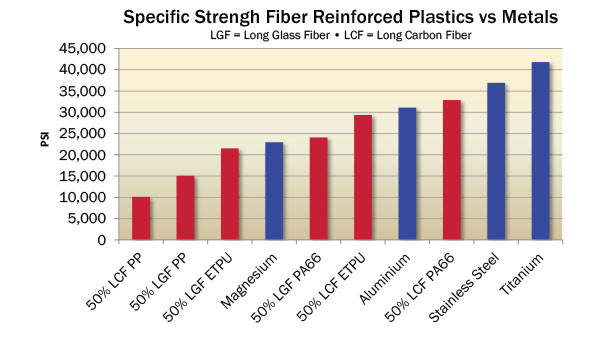

Long fiber composites are the pinnacle of structural performance in injection moldable thermoplastics. They combine high levels of stiffness, strength, and toughness together in a single material. Long fiber composites are often selected as substitutes for metals because of their high mechanical performance, as a replacement for under-performing plastics, or as alternatives to higher-cost engineering polymers through up-engineering of lower-cost plastics.

Composites offer:

• Stiffness

• Strength

• Toughness or durability

• Lightweighting

• Creep resistance

• Fatigue endurance

• Low temperature performance

• Heat resistance

• Dimensional stability

• Damping

• Design freedom

• Lower system cost

• Corrosion and chemical resistance

• Sustainability

• Radiolucent

• Thermal isolation

• Functional performance

Stiffness

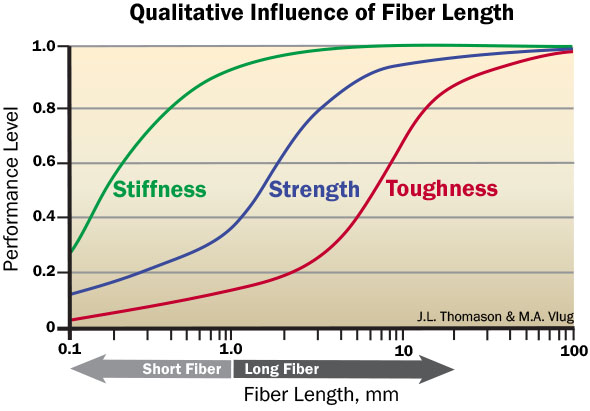

Adding fiber reinforcement to ductile thermoplastic polymers provides a substantial boost in modulus. This modulus gain combined with appropriate component design that includes uniform walls and underlying ribs and gussets, instead of thick wall cross-sections, significantly increases stiffness in molded articles.

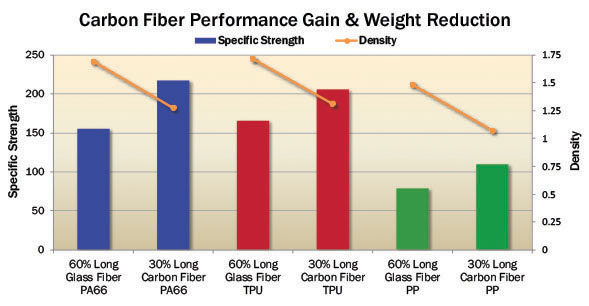

The type and amount of reinforcing fiber included in the composite contributes to increased stiffness. Carbon fiber increases modulus more than glass or natural fibers and a composite with 50% fiber will be stiffer than one containing 30%. Utilizing composites that offer more stiffness increases load carrying ability or allows designing with thinner wall sections to decrease material use and lower cost.

Stiffness gains through fiber reinforcement also translate to increased performance at elevated temperatures. Heat deflection temperatures (HDT), which provide an indication of short-term load carrying ability, increase significantly in fiber-reinforced materials over those of unmodified polymers.

Strength

Longer length, or higher aspect ratio, of reinforcing fibers provide long fiber composites with increased strength, which translates into the ability to resist deformation or creep under loads and higher fatigue endurance with minimal compression. More fiber filament enriched surface area provides the ductile polymer with more ability to grab onto and transfer stress to the stronger internal fiber skeleton formed during component molding.

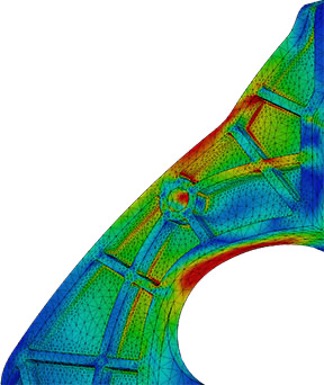

Orientation of reinforcing fibers within injection molded components also significantly influences composite strength. Although long fibers intertwine to form an internal structural skeleton providing reinforcement in all three planes, they also align in the direction of polymer flow as molds fill. To obtain maximum performance, mold designs should encourage fibers to align perpendicular to the direction of stress forces in key areas.

It is important to maintain maximum fiber length through careful control of processing parameters. Fiber length attrition can occur from shear in the injection molding press or from tight runner radii and improper gating in the mold. Significant reductions in median fiber length will reduce performance.

Toughness or Durability

Typically, stiffer plastics are more brittle. However, with long fiber composites the longer length of reinforcing fibers inverts that analogy. The higher aspect ratio of the fiber reinforcement facilitates more efficient energy transfer between the polymer and fiber filaments upon impact. The intertwined network of long fiber also aids in dissipating those forces throughout the composite structure instead of keeping them localized in one area.

The higher toughness of long fiber composites makes them among the most durable of injection molding plastic materials with structural characteristics. They are ideal for applications that experience repeated impact forces but need to retain their shape without permanent deformation or deterioration of function. Superior energy dissipation also increases their sound and vibration damping capabilities.

The inclusion of long fiber reinforcement helps composites resist cracking and impedes crack propagation by forming a robust internal fiber skeleton. Although long fiber composites offer excellent impact resistance, designs can permit failure at higher predicted loads to prevent damaging forces from transferring to adjacent systems. Longer fiber length also minimizes material fragmentation during failure.

Additionally, long fiber composites retain a significant amount of their durability at low and elevated temperatures making them desirable for devices exposed to varying climates.

Light Weighting

The high strength-to-weight ratio of long fiber composites makes them a suitable metal replacement medium for those seeking to reduce weight. In conjunction with proper component design, long fiber composites can provide the same level of mechanical performance as common die cast metals (ie: magnesium, zamak, and aluminum).

Light weighting or mass reduction is a core focus in aerospace and automotive markets where weight reduction facilitates increased fuel economy and decreases associated emissions. In this context, long fiber composites are eco-friendly alternatives to heavier materials. Using less of a higher performing material is not only a tactic to reduce weight but can also lower overall material costs, especially when fiber reinforcement is used to up-engineer the structural properties of a lower cost polymer or as a price diluent in higher cost engineering resins.

For many consumer items, weight reduction promotes in-demand portability along with increased functionality and improved ergonomics. Portability extends to sporting goods and tools where lighter weight components ease handling fatigue. With carbon fiber reinforced composites there can be additional perceived value added to products by consumers for utilizing “high tech” materials. This concept provides a competitive marketing advantage over products made from simpler plastics.

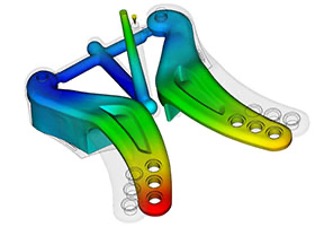

In metal replacement applications, long fiber composites are most successful when components take advantage of plastics' unique characteristics through redesign instead of attempting to use them as drop-in substitutes. Design analysis using computer simulations are especially helpful in attempting to duplicate structural performance attributes of metals in reinforced plastics as fiber alignment becomes a crucial design criteria.

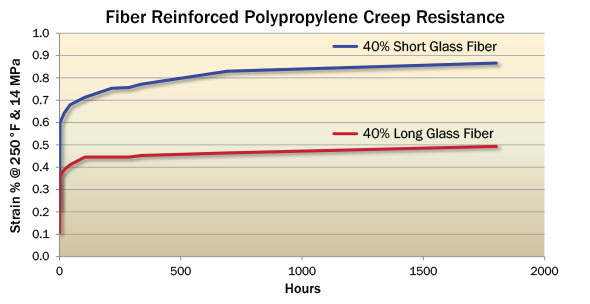

Creep Resistance

The amorphous and semi-crystalline morphology of thermoplastics can result in cold flow or creep effects if plastic articles are subjected to constant loads for long periods of time. Fiber reinforcement significantly stiffens and strengthens polymers to combat slippage in their molecular chains as they are subjected to long-term loadings. Reinforcing design elements can also be incorporated into plastic articles to gain additional stiffness and strength above the capabilities of the material alone.

Long fiber reinforced thermoplastics are able to accept nearly double the stress forces of short fiber compounds before load induced deformation begins to occur. As a general rule, load forces for plastic articles should be no more than half of the material’s maximum load capability to prevent creep from occurring.

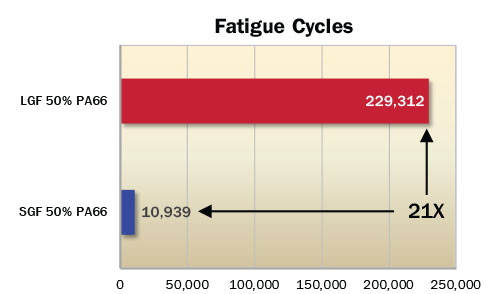

Cyclical Fatigue Endurance

Material fatigue from repeated force loading and unloading or bending flexure can result in unintended or premature material failure. The network of longer reinforcing fiber in long fiber composites increases its endurance to cyclical fatigue by dissipating stress energy over a wider region instead of having it localized in one area. Longer fiber length and its intertwinement also provides resistance to crack propagation. Crack formation can be an indicator of impending material failure.

Testing performed by PlastiComp has shown that long fiber composites can withstand over twenty times more bending flexure cycles in displacement scenarios than equivalent short fiber compounds; strategic reinforcement with unidirectional tape inserts can extend performance to over 400X.

Low Temperature Performance

The ductile nature of polymers combined with the higher fiber aspect ratio in long fiber composites allows them to retain more of their durability at low and elevated temperatures than other types of reinforced plastics.

Long fiber composites typically have similar impact performance at -60°F (-50°C) as they do at room temperature. Though elevated or high temperature performance corresponds to the morphology of the polymer and its glass transition temperature, long fiber reinforced thermoplastic will retain more of its structural performance longer than an unreinforced or short fiber reinforced plastic.

Heat Resistance

The modulus increase that long fiber reinforcement provides also increases heat resistance of the composite. Fiber reinforcement allows composites to retain more mechanical function at elevated temperatures and closer to the polymers glass transition temperature (Tg) than an unmodified polymer. Heat resistance for long fiber composites measured through deflection temperature under load (DTUL) or heat deflection temperature (HDT) provides an indication of the materials short-term load carrying ability at elevated temperatures.

Thermoplastics are viscoelastic materials. Their mechanical performance is subject to time at temperature influences present in usage environments as well as polymer morphological characteristics as they near their melting point. Composites using a semi-crystalline polymer matrix will retain some mechanical performance closer to the polymer’s glass transition temperature (Tg) than an amorphous polymer.

Heat Deflection Temperature @ 264 psi

| Nylon 6/6 | ETPU | PP | |

| Unmodified Polymer | 150°F / 66°C | 140°F / 60°C | 130°F / 54°C |

| Glass Fiber Reinforced | 485°F / 252°C | 200°F / 93°C | 305°F / 152°C |

| Carbon Fiber Reinforced | 485°F / 252°C | 200°F / 93°C | 275°F / 135°C |

Dimensional Stability (Shrink, Warp, & Thermal Expansion)

Long fiber composites are among the most dimensionally stable of injection moldable reinforced thermoplastic materials. All plastics are susceptible to some level of shrink as they solidify as this aids in their removal from the injection molding tooling. Typically, the amount polymers shrink is consistent and accounted for in component designs which enables the holding of tight design tolerances.

As reinforcements align in the direction of polymer flow as molds fill, this can lead to anisotropic properties. Anisotropic shrink can cause warping and distortion of components as they cool. Because of the higher fiber aspect ratio in long fiber composites, the fibers tend to intertwine to form an internal structural skeleton within injection molded components. This discontinuous fiber entwinement with long fiber composites results in improved dimensional stability with nearly isotropic shrink characteristics in comparison to other types of reinforcement which minimizes warp from differential cooling.

Long fiber reinforced composites also exhibit reduced thermal expansion compared to unreinforced plastics of the same type due to their internal network of reinforcing fibers providing resistance to deflection and form changes. This fiber network also helps components resist cooling sink formations in heavy wall sections.

Damping (Sound & Vibration)

Thermoplastics inherent ductility combined with the energy dissipation efficiency that provides long fiber reinforced composites with added toughness to resist impact forces also translates into good vibration and sound damping capabilities.

Intertwined segments of long fiber reinforcement create a conduit network through which stress energy is dissipated throughout a molded article instead of being localized in areas experiencing force. The viscoelastic nature of thermoplastic materials also aids in the absorption of energy instead of reflecting or transmitting it as vibrational or sound waves.

Design Freedom

In regard to plastics, the concept of design freedom incorporates several subtopics:

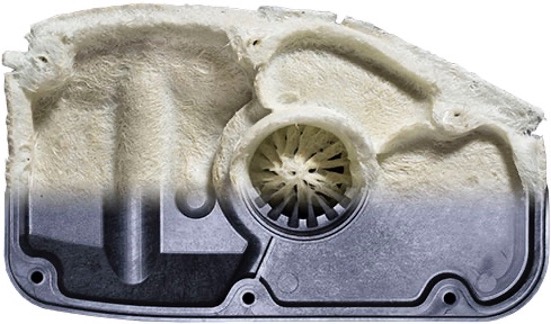

- Complex Geometry – Switching from methods of metal forming to injection molding long fiber composites allows production of components with more complex geometries. From sweeping curves to intricate details, designs that would be cost prohibitive to machine or difficult to cast in metals are easy and inexpensive to repeatedly produce in high volumes using injection molding processing.

- Parts Consolidation – The ability to produce more complex 3-D shapes leads to consolidation of parts and the elimination of corresponding production, secondary operations, and assembly steps to provide labor and time cost-savings. Injection molding can repeatedly produce net shapes in a single-step process that meet finished level specifications. Multiple components can be permanently joined together using laser, sonic, or thermal welding techniques.

- Improved Functionality – More organic and aesthetically pleasing designs allow for integration of functions and ergonomics that would not be practical in other material mediums. Such characteristics can be used to differentiate products produced using long fiber composites from competitors. Rigid thermoplastic structures are overmoldable with softer thermoplastic elastomers to improve ergonomics or add additional impact protection.

Lower System Cost

When deploying long fiber composites as a substitute for other materials, one needs to look beyond material cost alone. Long fiber composites are typically processed via injection molding which is a highly efficient method to repeatedly produce high quality components in large quantities. Plastics also require fewer finishing operations than other materials and their increased design freedom can reduce component count eliminating assembly steps.

When all the costs of producing a component are accounted for, using a material that is easier to work with can result in lower overall costs even if it is more expensive on a per pound or kilogram basis. More components can also be produced from lighter weight materials on a cubic volume basis.

Processing plastics requires low energy input producing favorable life cycle analysis (LCA) benefits and doesn’t create any toxic effluents. As a melt processable material, thermoplastics are reformable and recyclable.

Corrosion & Chemical Resistance

Steel can rust, wood can rot, and dissimilar metals used in tandem can lead to corrosion, but the inert nature of thermoplastic polymers makes them suitable for use in products with an indefinite life cycle.

Some polymers are susceptible to degradation when exposed to certain classes of chemicals and types of radiation. When selecting an appropriate long fiber composite, verify that the matrix resin is compatible with the intended usage environment and operating conditions your application will be used in, even if it’s intermittent exposure, to ensure compatibility with life cycle expectations.

Sustainability

As plastics have lower melting points than metals they require less energy input to fabricate components and processing doesn’t create any toxic effluents, thus producing favorable life cycle analysis (LCA) benefits. Color incorporated into the plastic matrix can eliminate secondary painting and finishing operations that produce undesirable VOC emissions. Lighter weight products also have lower transportation overhead, save on fuel efficiencies and its associated impact.

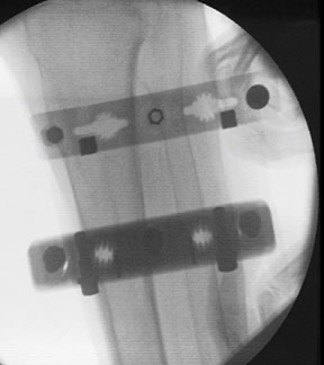

Radiolucent

Plastic radiolucent photoarticles are transparent to short wavelength radiation and appear nearly invisible on x-rays or during fluoroscopy procedures. Inclusion of additional additives into long fiber composites can render molded articles radiopaque for medical diagnostic procedures. Long glass fiber composites are safe to use in proximity with magnetic resonance imaging (MRI) and computed tomography (CT or CAT) scan diagnostic equipment because of their non-magnetic and electrically insulative characteristics.

Radio transparency and high dielectric properties makes long glass fiber reinforced thermoplastic an ideal material for consumer electronic items that utilize wireless transmission technologies.

Thermal Isolation

Thermoplastics have a lower thermal conductivity than metals; this provides a consistent and more comfortable tactile feel during handling at low or elevated temperatures which can be highly desirable. Incorporating special additive technologies into long fiber composites can facilitate thermal transfer if heat dissipation capability is needed.

Functional Performance

The inclusion of additives in addition to fiber reinforcement can provide thermoplastic composites with valuable performance enhancements that can expand their functionality and allow the creation of more effective products. This can include technologies such as enhanced UV performance and heat stabilization.

- Wear Resistant – Add wear (surface abrasion and friction) resistance by incorporating internal lubricants that migrate to the surface to reduce maintenance and increase reliability or minimize noise between connected moving parts.

- Conductive – Modify the inherent electrical insulative nature of plastics with additive technologies to render them antistatic, static dissipative, conductive, or to provide EMI shielding characteristics.

- Flame Retardant – Increase product safety by including flame retardants to provide halogen-free fire resistant/smoke density/smoke toxicity (FST) and UL94 compliance.

- Color – Custom colors modify appearance to increase consumer appeal and ease identification. No longer do you need to compromise and receive only black parts to obtain structural performance. Polymer flow enhancers and optimized processing produce smooth, resin-rich surface finishes free of visible fibers.