Overmolding: TPE Selection

GLS™ Product Line

There are a variety of GLS™ soft touch TPEs designed to have excellent adhesion to a number of rigid plastic substrates. The table below summarizes the standard grades that are currently available and their corresponding substrates.

If you do not see your substrate in this table, please contact GLS directly; we can develop a custom TPE that is optimized to bond to your specific substrate.

|

Substrate |

Typical Applications |

Recommended TPEs |

|---|---|---|

|

Polypropylene |

Personal Care - Toothbrushes, Razors, Pens, Sports-Grips, Handles, Knobs, Flaps, Power & Hand Tool Handles, Grips, Caster Wheels |

Dynaflex |

|

ABS |

Housewares, Toys, Portable Electronics, Grips, Handles, Knobs |

Versaflex OM |

|

Polycarbonate |

Handheld Electronics, Business Equipment Housings, Sporting Goods, Healthcare Devices, Hand and Power Tools, Telecommunications and Business Machines |

Versaflex OM |

|

PC/ABS |

Housewares, Toys, Portable Electronics, Grips, Handles, Knobs, Hand and Power Tools, Sports and Leisure Equipment, Telecommunications and Business Machines |

Versaflex OM |

|

Nylon 6 and 6/6 |

Hardware, Lawn and Garden Tools, Power Tools |

Versaflex OM |

|

Propionate |

Toothbrush Handles, Eyewear, Cosmetic Packaging |

Versaflex OM |

|

Copolyester |

Toothbrush Handles, Cosmetic Packaging |

Versaflex OM |

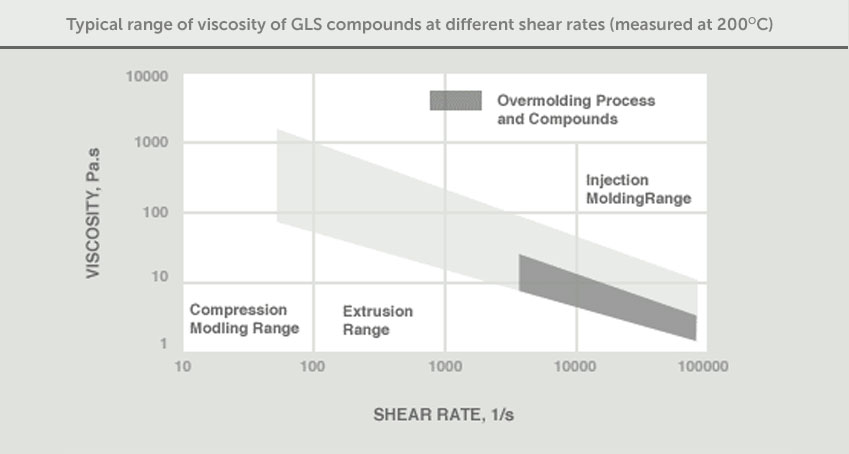

Material Flow Behavior

GLS overmolding formulations have relatively low viscosity characteristics. They are shear responsive and their viscosity is reduced when they are processed at high shear rates. This helps them flow into thin-walled sections commonly encountered in overmolding. The figure below illustrates the effect of shear rate on the viscosity of GLS overmolding TPEs. For the viscosity of a specific grade, refer to the individual Product Technical Datasheet.